Today let's take a look at the internal structure of the Pogo Pin and discuss what are the advantages and disadvantages of different Pogo Pin structures.

Do you know how many Pogo Pin internal structure there are in UPE company?

Today let's take a look at the internal structure of the Pogo Pin and discuss what are the advantages and disadvantages of different Pogo Pin structures.

Below is Structure description:

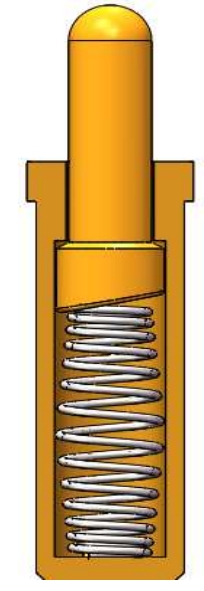

A. Plunger for oblique bevel Pogo Pin

Advantages: Conventional use, impedance stability and long life.

Disadvantage: Processing is more difficult than C structure.

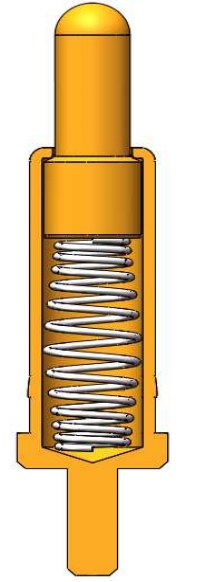

B. Plunger for drilled Spring Pogo Pin

Advantages: In a limited space, the plunger can perform maximum compression.

Disadvantage: Impedance is unstable, the current is under 1A(less than 1A). When the spring force is too small, the working life will be attenuated.

C. Plunger for flat Spring Loaded connector

Advantages: Turning is easy to machine, for space structure based on A&B

Disadvantage: The impedance is unstable relative to A but higher than B. Generally, this method is not used.

D.Barrel inside added insulating beads Pogo Pin connector

Advantages:The impedance is more stable, suitable for current use above 10A.

Disadvantage:The cost is high and the assembly process is difficult

E.Both sides of the plunger can be compressed Spring Pin Advantages: Save space of structure, long distance, large compression board to board contact Disadvantage:In case of improper use of the structure, the spring will fail F. Four-piece combination Pogo Pins

Advantages: High press smoothness, plunger deflection small, waterproof and dust proof. The working life is relatively longer. Over pressure will not cause product failure.

Disadvantage:High cost, limited space structure for use

G. Intermediate shaft compression

Advantages: Simple structure, can pass high current.

Disadvantage: Product use is limited to spatial structure

H. Ball compression contact

Advantages:Simple structure and easy processing

Disadvantage: The compression stroke is too small and the assembly size is unstable.